I’ve been sitting on this for a while, and I finally have some time (not much) to post something.

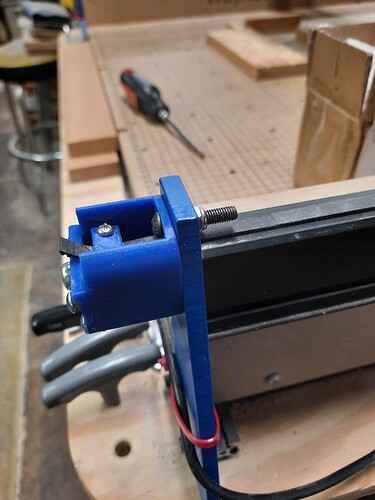

A while ago, an individual on the C3D forum asked me about creating a simple belt tensioner for his machine, a Shapeoko 3. I came up with this.

Someone here was watching and asked me to make an X-Carve version, so I did.

The short of it is that you can fine tune the belt tension by simply turning an M5 screw. The downside is that you need to cut a slot in some of your end plates (fairly easy to do in place, REALLY easy to do when disassembled).

Here are some renders and pics from my Beta tester on an X-Carve with upgraded plates…works the same on a standard X-Carve.

If anyone is interested, I will put the files up on Thingiverse.

8 Likes

Niel can you explain how this is an improvement from the current adjustment that is on the X-Carve?

Am I missing something?

1 Like

To be honest, Mark, not much different. The concept is the same, just moved to the outside.

A couple of positives:

-

No folding belt, so the belt has the same tension the entire length of the the extrusion.

-

Easier to install new belts.

-

More tensioning range.

-

Ideal for steel core and Kevlar belts (no folding)

It’s really just a solution for those who are looking for one. If you search this forum, there have always been issues with belt tension.

Do I like them better than those L clips? Absolutely.

Is it worth the effort in cutting slots for the belts? Only if you have belt tensioning issues. I haven’t messed with the tension on my machine at home in a couple of years.

This is awesome! I’m going to forward this over to our product team to keep in mind for future designs.

@LukeWilson

1 Like