I just upgraded my X-carve 1000. Everything is working great, But when I was planing some wood I noticed that it was not cutting level on my X Axis. So it was leaving a slight angle across the wood with every pass. So really its not X or Y axis but the level of the Router. Question is how to I fix this. My Gantry is level with the machine but I noticed that when I get out to the router it is a little off. What is the best way to resolve this problem?

check your v wheels make sure there no play and/or movement - rocking

It’s kinda hard to tell if I understand what you’re saying…

Either you mean that the X and Y are not perpendicular to each other (the frame needs squared) (but i think you’re saying it’s not this)

OR

you mean that the Z is not moving across the machine on a plane parallel to the wasteboard (aka the wasteboard needs surfaced)

OR maybe you mean the spindle is crooked, not perpendicular to the wasteboard AFTER it’s been surfaced (the spindle needs trammed)

???

If you added the risers, then the gantry parellel to wasteboard can certainly be different than b4, and the wasteboard might just need re-surfaced, which should be done routinely anyway as the MDF changes shape with moisture content as the seasons change…

Many people add a secondary wasteboard as well…

I already checked the v wheels and they seem fine. Made small adjustments to them, but did not change the cut.

Seth, The problem is when my plaining bit cuts across the wood, the back side of the cut is higher then the front side closest to me. So from left to right and right to left cuts, the closer to me the lower the cut and the back of the cut is higher. So my Gantry is level to the board. I noticed that it seems like the spindle is off level. That the top of the spindle is leaning forward toward me causing the back side of the bit higher. I was thinking of adding a spacer(very thin washer) to the bottom bolts of the spindle mount. I do not see any other way to level this.

Mine does the same thing. I am pretty sure the Z axis could rotate a little to take care of it, but I’m not sure that there is enough room in the bolt holes to do it. Probably a slot instead of holes for eccentric nuts could do it. Probably a half a degree would be the solution. In my mind I see an adjustable bolt on its side to adjust the pivot. Precision machining costs a lot of money and I think there is a tradeoff to part manufacturing tolerances for these parts. Ideally you’d want parts manufactured on a VMC. Just my thoughts on it. I just deal with it.

Sorry you have the same problem, but it makes me feel a little better that I am not the only one with this problem. I am going to try a few things today. If I find a fix I will let you know.

I have a cnc4newbies Z axis too, so those tolerances added to the Xcarve part tolerances…If you want milling machine perfection you have to pay milling machine prices…As I said there’s a tradeoff, cost vs perfection. You can get pretty close though. You can see the ridges in my basswood. Some of it may be router flex too.

I like how the upgrade works, but my old set up really had no issues. I just wanted to be able to work a little faster and the clearance is a plus.

Randy,

You have four button screws on each end of the master slide, just loosen them up. lower the “Z” down to the waste board (you might need a block of wood under the spindle, or an old end mill installed). zero out your “Z” and then some. to compensate for the weight of the new “Z” axis and tighten the button screws up and you should be good to go.

Wow, that makes sense. I also noticed some almost binding noise when I use the Z . was going to ask about that. I will let you know how it works thanks!

now that binding noise you have to live with, another word belt drive is quite direct equals’ noise.

try increase the plunge rate, some noise will dissipate another word will be Quiter.

Ken I made the adjustment like you said, It helped but did not totally fix it. But now it is where I can work with it. Thanks for the help!

well, if you need perfection. I believe Seth mention about shimming out your “Z” at bottom or top of the assembly. depending on what needed.

I misunderstood the original issue, sounds like Ken took you pretty far through the process…

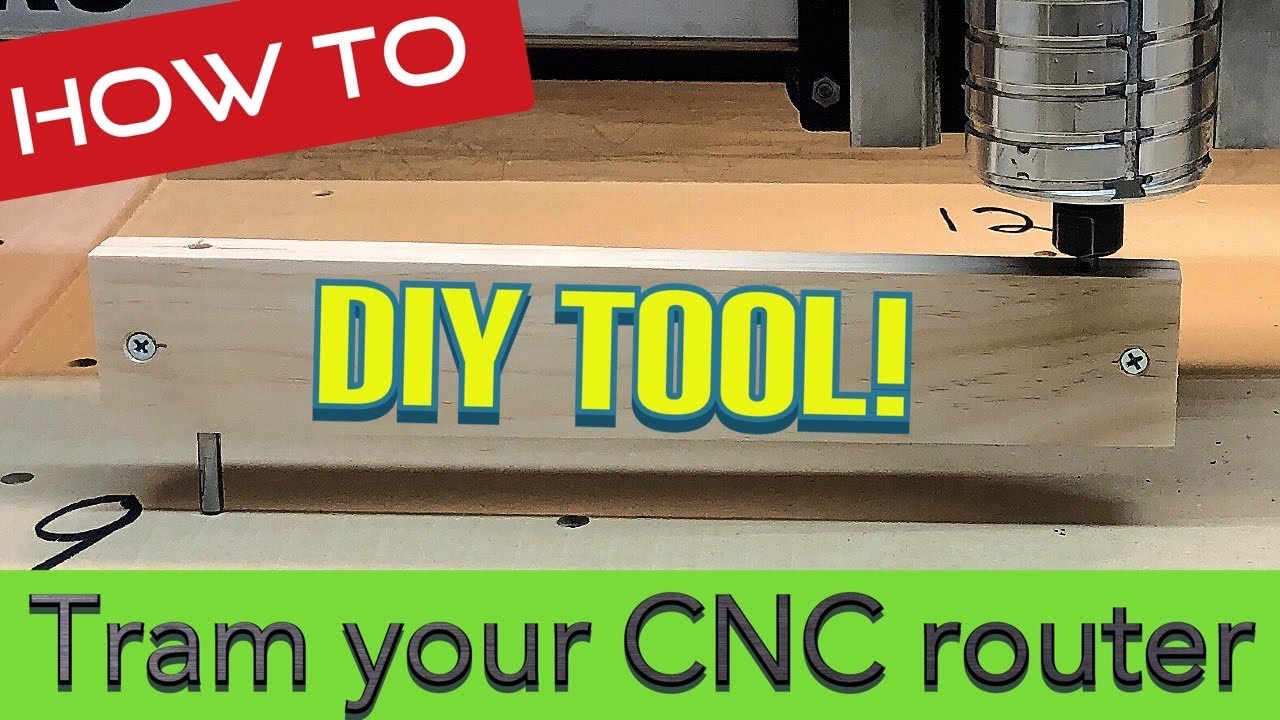

you may need to tram the router mount clamp… some ppl use a beer can aluminim OR folded up aluminum foil to make a shim and tilt the router clamp where it mounts to the Z plate… it becomes a tedious process to get perfect, but here’s a tramming video showing that process, unfortunately Tim breaks one major rule in tramming in this video, he didn’t surface the board he’s tramming to… the board (or wasteboard) being used to set tram needs to be surfaced FIRST, then tram set, and then re-surfaced, and possible repeated… personally I use a large MDF board that isn’t the actual wasteboard, that way I’m not thinning out my wasteboard during the tramming process…

Also, you don’t really need Tim’s 3d printed holder or the gague.

instead you can get the job done with one of these…

Thank you so much for the help. I will let you know how it turns out.

Just wanted to thank you guys. I ended up putting spacers in and now its not perfect but really really close. I really like the upgrade now. Thanks again for the help!

Hi Randy,

I have the same issue as you. I surfaced the waste board and it left ridges on the surface because the gantry was slightly tilted forward and the forward edge of the 1" bit was lower. I didnt know what was wrong at the time and I did the whole surfacing anyway and it worked for a bit. After replacing my spindle with a 1.5Kw spindle I again checked the tram and it was WAY off. I loosened the 4 screws on the gantry and had to use a large pipe wrench to twist it back and tighten. After all that it is still slightly forward. Im going to have to shim as well. Best of luck to you.

This topic was automatically closed 90 days after the last reply. New replies are no longer allowed.